NIKKEL ALLOY PIPE SEAMLESS STEEL PIPE

Beskriuwing

| Materiaal | Monel / Inconel / Hastelloy / Duplex Steel / PH Steel / Nikkel Alloy |

| Foarm | Rûn, Forging, Ring, Coil, Flens, Disc, Folie, Sferysk, Lint, Fjouwerkant, Bar, Pipe, Sheet |

| Klasse | N02200, N02201, N04400, N06600, N06601, N06625, N06690, N08810, N08825, N08020, N08020, N08028, N0802801, N0802801, N0802801, N0802801 5、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS314 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spesifikaasje | Oaren: 253Ma, 254SMo, 654SMo, F50 (UNS S32100) F60, F61, F65, 1J22, N4, N6 ensfh |

| Legearing :lege 625, Alloy 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Searjes:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Timmerman 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Inkoloy:Inkoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Wire: 0.01-10mm Strip: 0.05 * 5.0-5.0 * 250mm Bar: φ4-50mm; Lengte 2000-5000mm Pipe: φ6-273mm;δ1-30mm; Lengte 1000-8000mm Blêd: δ 0.8-36mm; Breedte 650-2000mm; Lengte 800-4500mm | |

| Produkt Skaaimerken | 1. Neffens de tarieding proses kin wurde ferdield yn deformation superalloys, casting superalloys en poedermetallurgy superalloys. 2. Neffens it fersterkjen modus, der binne fêste oplossing fersterkjen type, delslach fersterkjen type, okside dispersion fersterkjen type en fiber fersterkjen type, ensfh |

| Standert | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Ynspeksje | ISO, SGS, BV, ensfh. |

| Oanfraach | Hege temperatuer komponinten lykas turbine blades, guide vaes, turbine skiven, hege druk compressor skiven, machine manufacturing en ferbaarningskeamers brûkt by de fabrikaazje fan loftfeart, marine en yndustriële gasturbines |

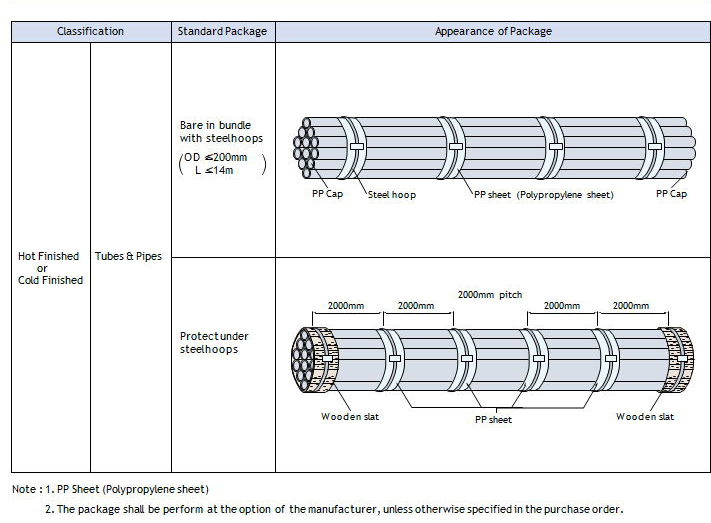

| Ferpakking | 1. gefallen ynpakt yn houten gefallen 2. papier ferpakking 3. plestik ferpakking 4. foam ferpakking Ferpakking neffens klant easken as produkten |

| Befalling | 7-25 dagen of neffens it produkt |

| Betelling | L / C, D / A, D / P, T / T, Western Union, MoneyGram, neffens klant easken betellingen foar offline oarders. |

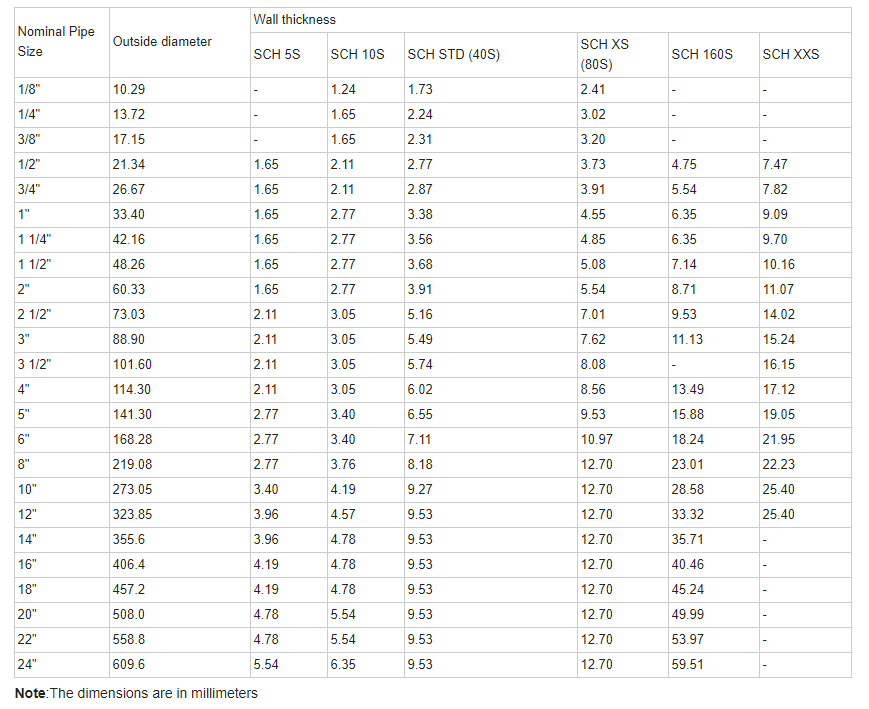

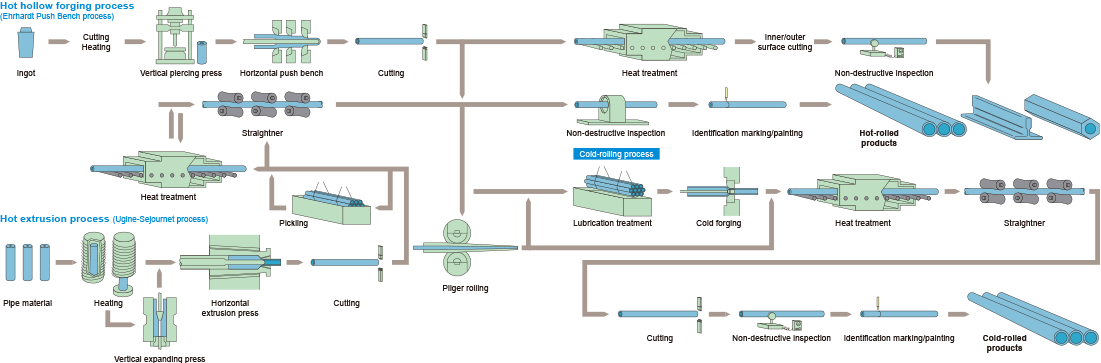

Spesifikaasje

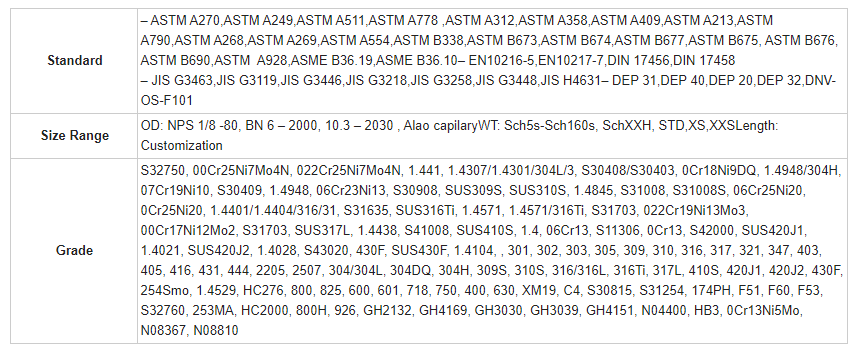

Standert

Skilderjen & Coating

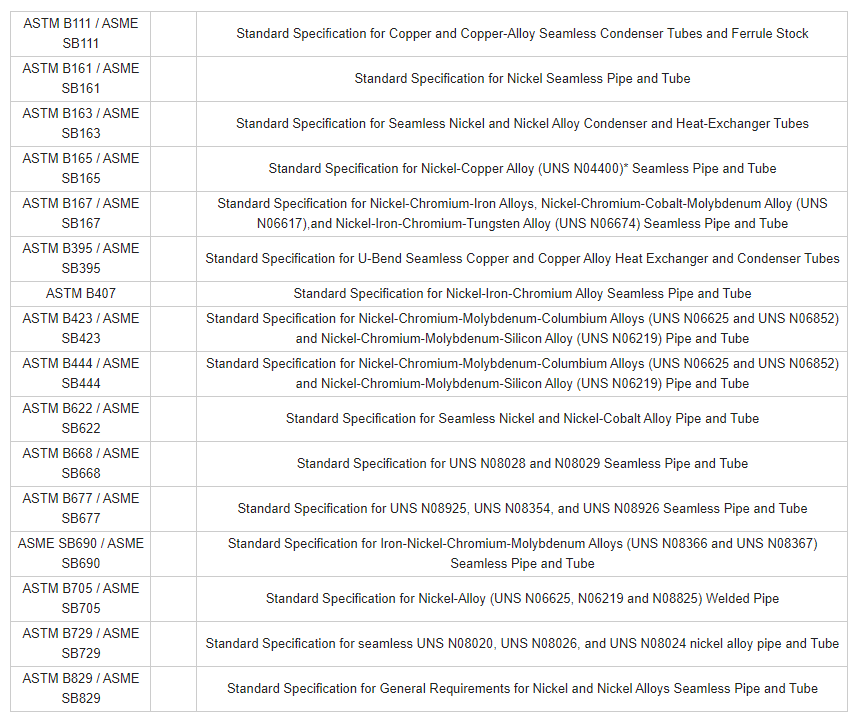

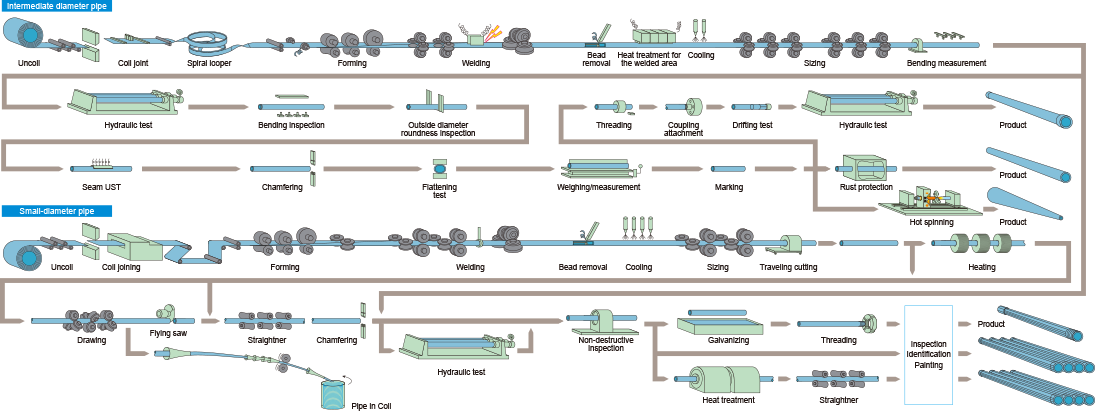

Naadleaze stielen piip

Welded stielen piip

Ynpakke & Laden

Skriuw jo berjocht hjir en stjoer it nei ús